Robotic Systems

Robotic machine tending is loading and unloading to CNC machines using a Robot. The CNC machines can be combination of turning centers and VMC or HMC.

Robotic Machine Tending

- A single Robot can load/unload upto 3 CNC machines depending on robot reach and machining cycle time

- We provide all the required infeed and outfeed systems

- Safety fencing is provided for the entire cell with a safety door interlock

- Robotic machine tending is suitable if the component has machining required in all the machines inside the cell.

- Running different models of components is also possible with minor quick changes to the cell like gripper fingers and locating pins. The models can be of different diameter or lengths.

- Suitable for CNC machines as well as Press

- 1 Operator will be able to manage 2 to 3 robotic cells

- Robots can also be mounted on a floor mounted or gantry mounted 7th axis if tending of more than 3 machines is required

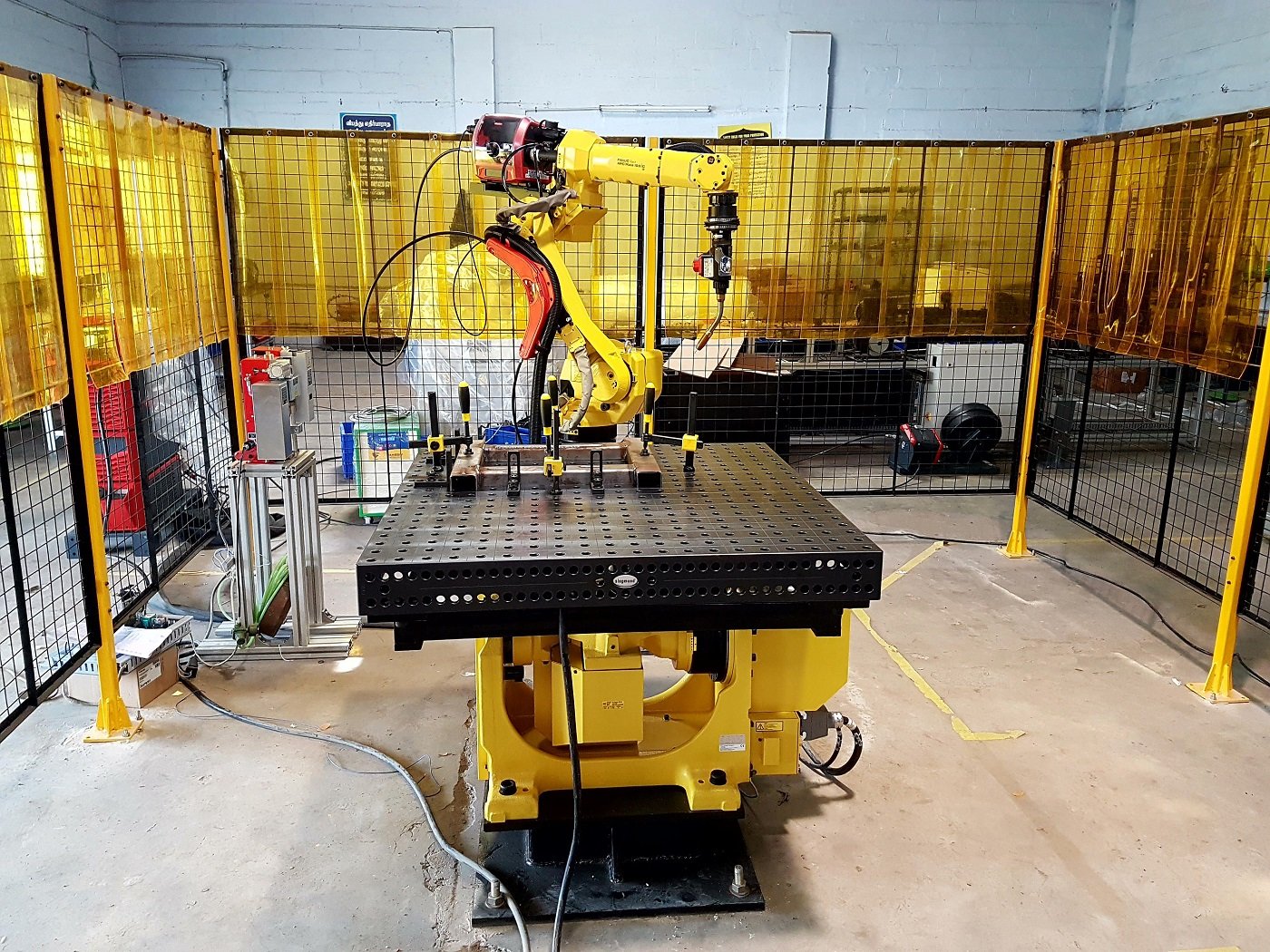

Robotic Welding

- Robotic welding systems are the need of the hour today as welding is a hazardous environment and also accuracy is required.

- Welding controllers like Fronius, Kempi and Lorch can be integrated with robots like Fanuc, ABB, Kawasaki, Kuka, Yaskawa and Nachi

- Typically 10 to 12 Kg payload 6 axis robots are used for welding

- The welding fixture can be on a stationary table or mounted on a 2 axis (7th and 8th axis) table integrated to the robot controller and move synchronous to the robot axes during welding so that the robot can reach certain locations in the component

- In certain cases the robot can also be moving on a floor mounted or gantry mounted 7th axis to weld on multiple fixtures. In this case the operators can be setting up one fixture while the robot is welding on the other fixture

- Both spot welding as well as arc welding is possible with robotic solutions

- MIG and TIG can be done as the requirement defines.

Robotic Painting

- Robotic painting systems are very much required because of the hazardous environment and difficulty in finding manpower.

- We can provide painting and Teflon coating solutions.

- The same robot can also pick and place the components before doing the painting.

- The components can be positioned on a stationary table or can move in a conveyor while the robot is painting.

- The robot can also be mounted on a floor mounted or gantry mounted 7th axis if painting is required on multiple fixtures.

- Upto 25% savings in paint/Teflon material compared to manual painting.

7th Axis Solution

- Robots can be mounted on a floor mounted or Gantry mounted 7th axis to service more machines.

- We provide Rack and pinion as well as toothed belt based solutions.